Industrial Panel Sawmill Line Equipment With Gasoline Engine

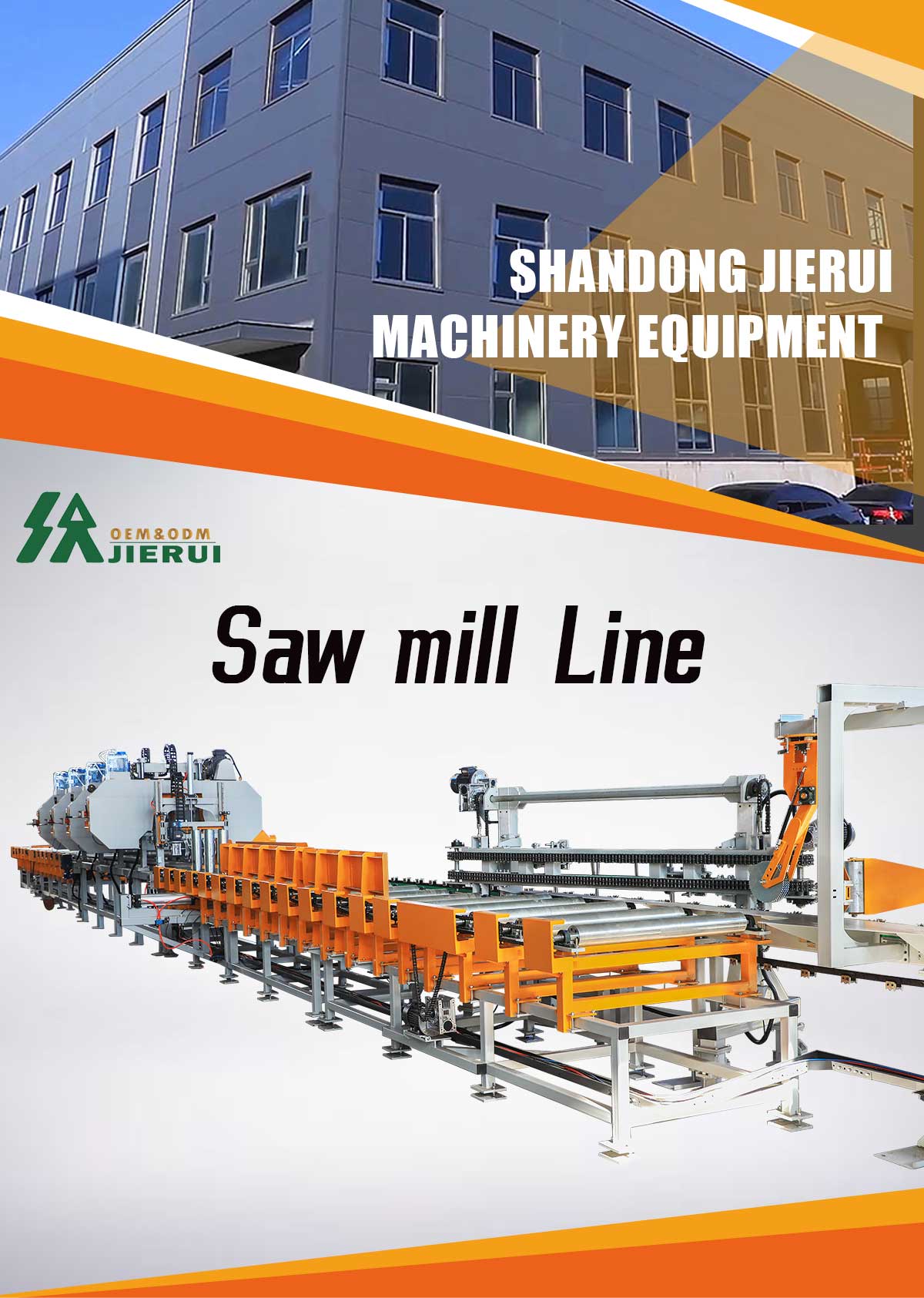

A sawmill line typically refers to a complete, automated system for processing logs into lumber or other wood products. This system involves multiple machines and processes that work together seamlessly to maximize efficiency, precision, and productivity.

Make an inquiry will get the best shipping quotation

A sawmill line is an integrated, automated system that transforms raw logs into finished lumber with minimal manual intervention. From the moment the logs enter the system, each machine in the line works in harmony to maximize productivity, ensure precise cuts, and maintain safety standards.The process typically involves debarking,cutting, planing, and sorting, with advanced technology to optimize every step. This seamless coordination not only enhances the quality of the finished product but also significantly improves operational efficiency and reduces labor costs.

Increased Efficiency with High-Volume, Simple Design, and Low-Cost Sawmill Line Equipment Jierui Industrial sawmilling equipment is designed for high yield and cost-effective operations, offering a simple yet robust design that maximizes wood processing efficiency. Our sawmill systems can process wood without the need for sorting and peeling, delivering high performance even in limited production spaces while maintaining low energy consumption.

Key Benefits of Jierui Industrial Sawmill Lines:

1. Ability to Process Larger Logs (Up to 45 cm Diameter)

Jierui sawmill lines can handle logs up to 45 cm in diameter, significantly surpassing the 35 cm limit of many competitors. This capability allows for processing larger logs, which reduces the cost per centimeter and increases the overall yield from each log.

2. No Need for Log Sorting

Our industrial sawmilling systems can efficiently process logs ranging from 15 cm to 45 cm in diameter without the need for prior sorting. This eliminates additional investment in sorting equipment, saving both energy and labor costs, while also freeing up valuable space.

3. Labor and Cost Savings

By removing the need for sorting, storage, and extra processing steps, Jierui sawmill lines reduce both labor and energy costs. The ability to process logs with bark further cuts down on production expenses, making the entire ope ↓ on more efficient and cost-effective.

Product details

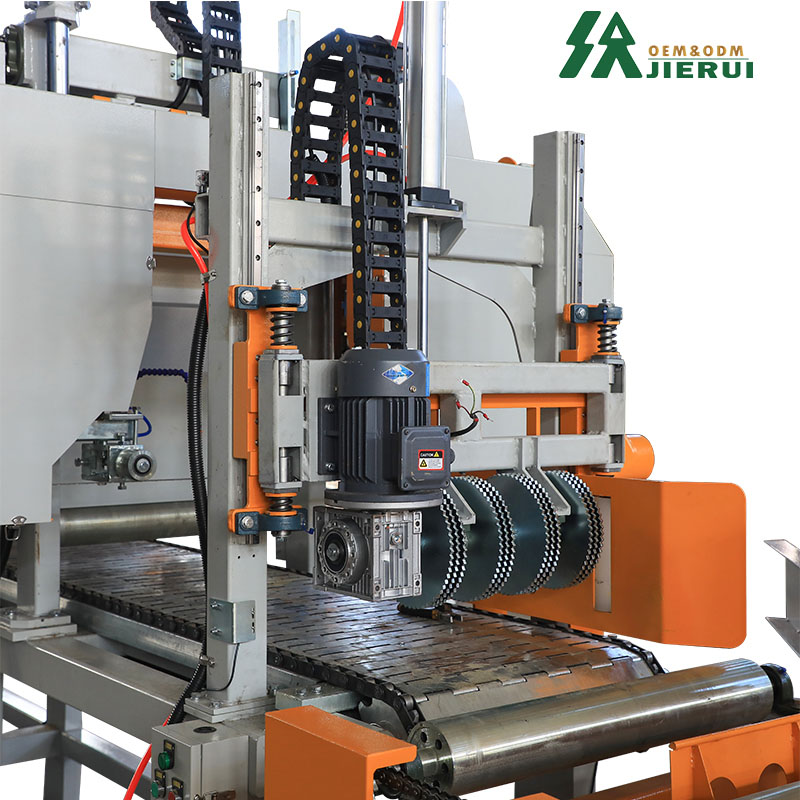

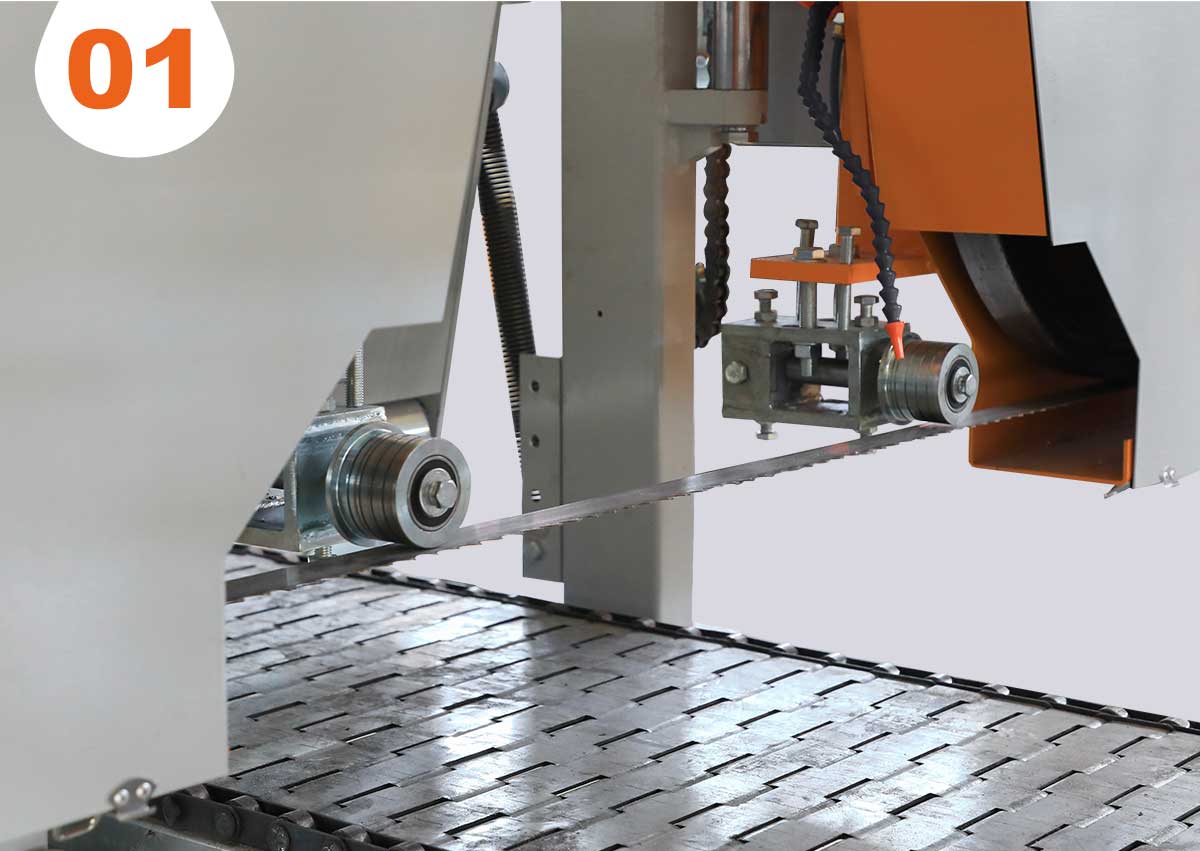

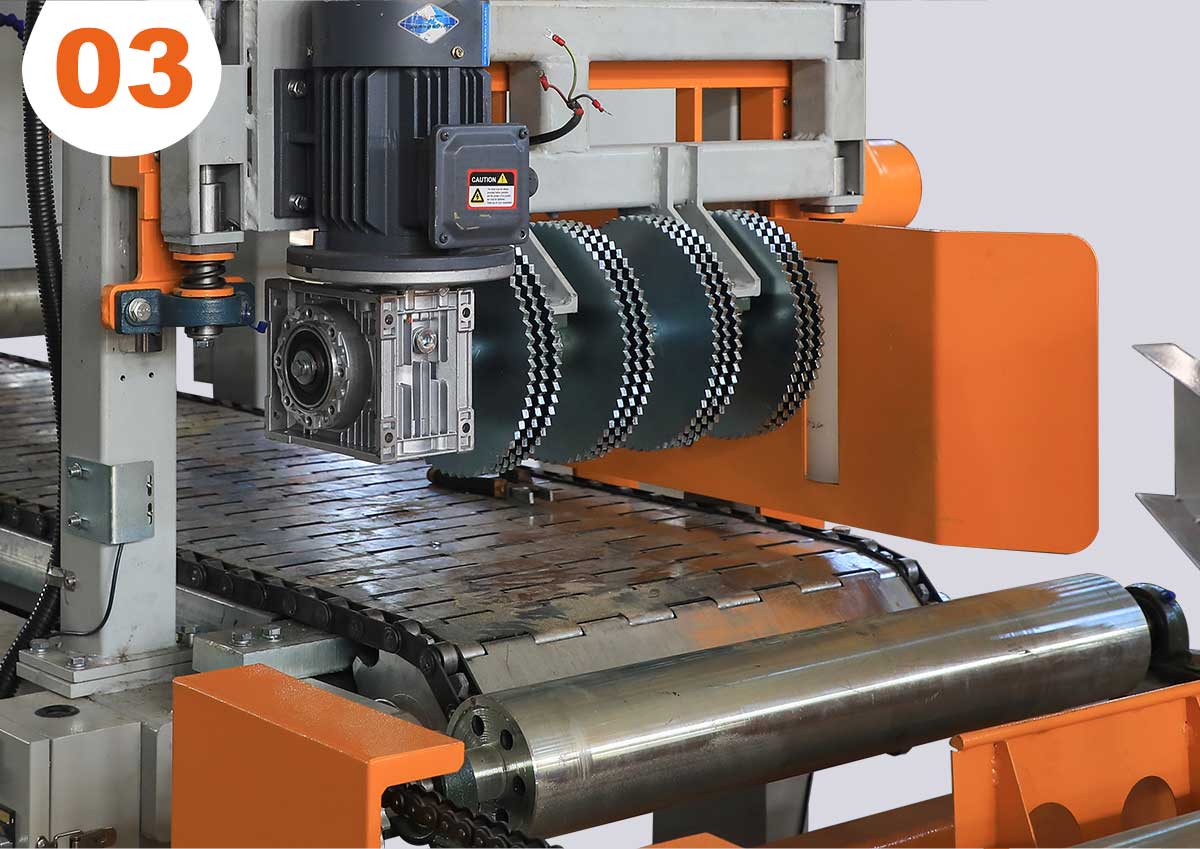

The saw blade roller guide device ensures precise alignment and smooth movement of the saw blade during operation, reducing wear and tear. The **band saw blade cooling system** helps maintain optimal temperature, preventing overheating and prolonging blade life, while ensuring smooth and accurate cuts.

A log press wheel is used in sawmills to apply pressure on logs, ensuring they remain securely in place during cutting. It helps stabilize the log as it moves through the saw, preventing shifting or rolling, which improves cutting accuracy and safety. The press wheel can be adjusted to accommodate different log sizes and ensures consistent feed to the saw blade.

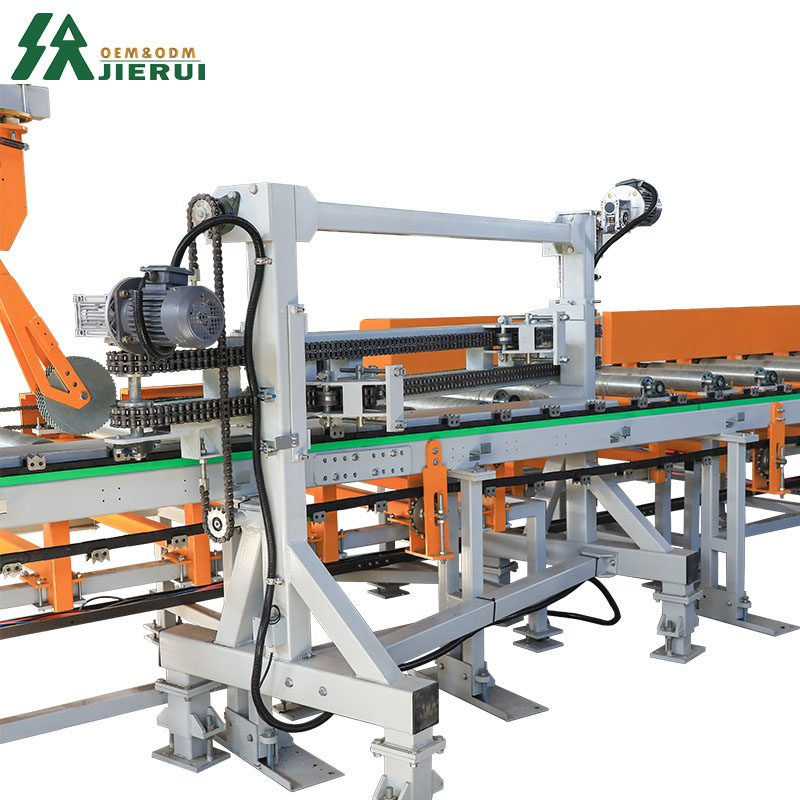

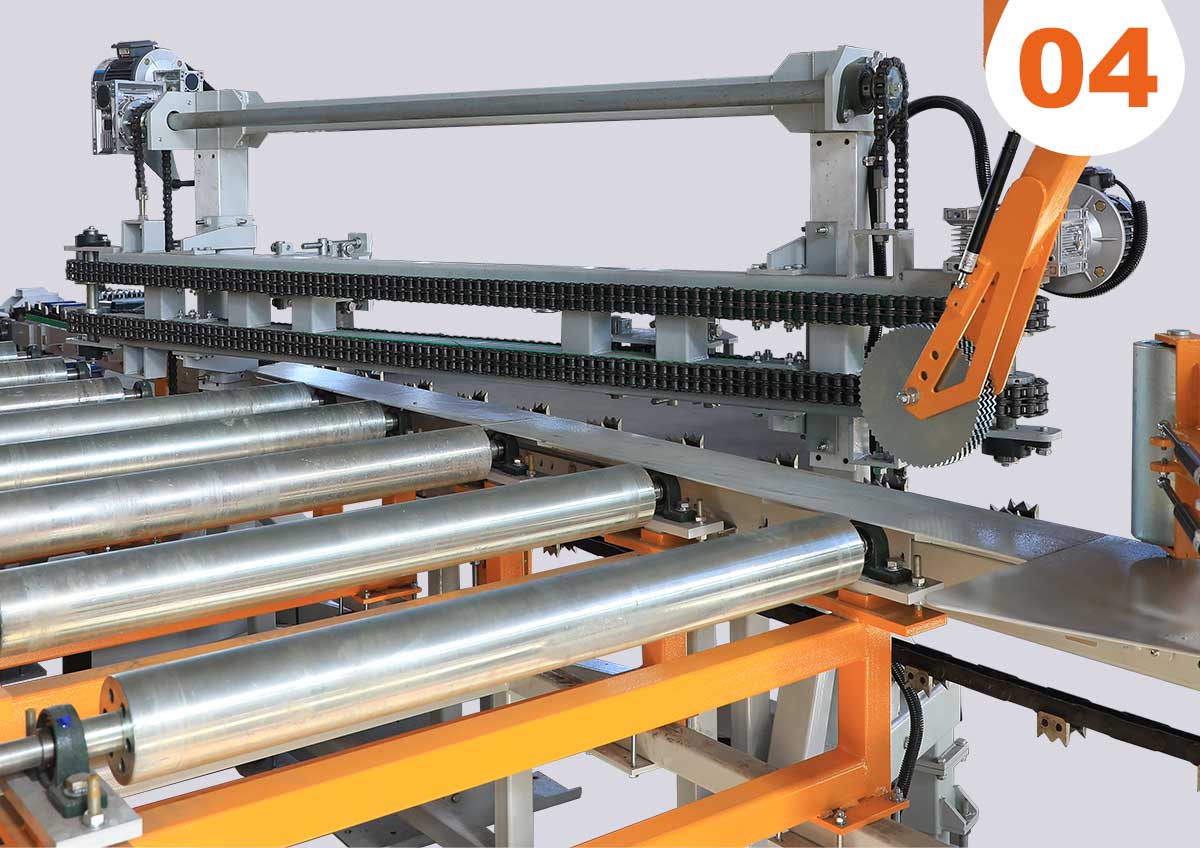

Automatic log feeding refers to a system in sawmills that automatically moves logs into position for cutting. This system typically uses conveyors, hydraulic lifts, and rollers to feed logs into the sawmill, reducing the need for manual labor. It enhances productivity, minimizes human error, and ensures consistent log positioning for accurate cuts. The automated process increases efficiency and safety by streamlining log handling and reducing operator fatigue.

A bark separator is a device used in sawmill lines to separate bark and wood chips from usable wood materials. It efficiently removes bark debris generated during debarking or sawing, ensuring cleaner wood output and reducing waste. By sorting and collecting bark separately, it improves overall production efficiency and keeps the working area cleaner, while allowing bark to be reused for biomass fuel or mulch.

A log loading rack is a structure used in sawmills to hold and organize logs before they enter the processing line. It allows for efficient loading, positioning, and storage of logs, ensuring a smooth and continuous feed into the sawmill. The rack helps improve workflow, reduces manual handling, and increases overall productivity by keeping logs readily accessible for automatic or manual feeding systems.

Workflow

Sawmill Line Workflow: Logs

1. Debarking

* Purpose: Remove the outer bark from the logs. This is essential for clean, high-quality lumber and to prevent debris from

affecting saw blades.

* Process: Logs are fed into a debarking machine, which uses rotating rollers or a mechanical scraper to strip off the bark.

2. Sawing

* Purpose: Cut the logs into rough boards or billets. This is often the first step in transforming a log into usable lumber.

* Process: The log is passed through a sawmill, which can be a band saw, circular saw, or frame saw, depending on the

equipment.

3. Re-Sawing

* Purpose: Further reduce the thickness or dimensions of the boards produced in the sawing step to achieve desired sizes.

* Process: The rough-cut boards are reprocessed in a re-sawing machine, which cuts them into thinner sections or planks.

4. Edging

* Purpose: Trim off the irregular or rough edges of the boards to create a uniform width and improve appearance.

* Process: The boards are passed through an edging machine that cuts off the excess, often producing straight-edged lumber ready for further processing.

Product display

Come to us for pricing!

Contact us today for a free product brochure containing detailed product information, inspiration and insights.

Related Products

Related News

Submitted successfully

We will contact you as soon as possible