Automatic Bandsaw Mill Machine For Woodworking Machinery

1.Automatic Feeding System:

Logs are automatically fed into the cutting system using conveyor belts or rollers. The system can handle logs without manual loading, reducing the need for labor and speeding up the process.

2.CNC Control System:

Features Computer Numerical Control (CNC) technology for precise cutting and minimal waste. The system is typically customizable, allowing users to set up various cutting patterns and dimensions.

Make an inquiry will get the best shipping quotation

Industrial Panel Sawmill Equipment is a fully automated, computer-controlled timber processing solution engineered for high production, precision milling, and optimized lumber recovery. It combines rugged construction with advanced CNC automation, enabling efficient conversion of large logs into dimensional lumber with minimal manual intervention.

Why Choose the Auto Sawmill?

Choosing an Automatic Sawmill means investing in higher efficiency, precision, and long-term profitability. Compared with manual or semi-automatic solutions, an auto sawmill delivers clear advantages for modern wood processing operations:

1. Fully Automated Operation

Automatic log loading, clamping, feeding, and cutting significantly reduce manual labor. One operator can control the entire process from a console, improving safety and productivity.

2. High Precision & Consistent Output

CNC/PLC control systems ensure accurate cutting thickness and repeatable results. This minimizes material waste and guarantees uniform lumber quality, even when processing large or irregular logs.

3. Higher Productivity & Yield

With continuous feeding and optimized cutting paths, auto sawmills dramatically increase throughput. More boards are produced from the same log, maximizing wood utilization and profit.

4. Labor Cost Savings

Automation reduces reliance on skilled labor and lowers operator fatigue. Fewer workers are needed to achieve higher production volumes, reducing overall operating costs.

5. Enhanced Safety

Integrated safety protection systems—such as automatic emergency stops, guarded cutting areas, and stable hydraulic clamping—create a safer working environment.

6. Strong Adaptability

Auto sawmills can handle logs of different diameters and lengths without frequent manual adjustment. This makes them ideal for mixed wood processing and high-volume operations.

7. Durable, Heavy-Duty Design

Built with reinforced frames, precision rails, and wear-resistant components, automatic sawmills are designed for long-term, high-intensity industrial use with minimal maintenance.

8. Smart & User-Friendly Control

Touchscreen interfaces, multilingual support, and preset cutting programs make operation simple and efficient, even for less-experienced operators.

| Sawmill parameters | JR1000D | JR1300D | JR1600D | JR2000D |

| Max Log Cutting Dia(cm) | 100 | 130 | 160 | 200 |

| Max Log Cutting Dia(inch) | 39 | 51 | 63 | 79 |

| Max Log Cutting Length | 4.5m | 4.5m | 4.5m | 4.5m |

| Track Length | 6m | 6m | 6m | 6m |

| Gasoline/Diesel engine | 22 HP | 25HP | 25/30HP | 30HP |

| Engine starting mode | Electric starting | Electric starting | Electric starting | Electric starting |

| Packing Size | 3.5*2.2*2m | 20 'container | 20 'container | 40 'container |

| Saw Wheel Diameter | 770mm | 770mm | 900mm | 1100mm |

| Saw blade width | 85mm | 85mm | 85mm | 110mm |

| Lifting | Auto | Auto | Auto | Auto |

| Walking | Auto | Auto | Auto | Auto |

| Safe cutting Speed | 6m/min | 6m/min | 4m/min | 4m/min |

| Weight | 3000kg | 3800kg | 4500kg | 6000kg |

| Warranty | 1 year | 1 year | 1 year | 1 year |

| Color customization | Supported | Supported | Supported | Supported |

| Logo customization | Supported | Supported | Supported | Supported |

Product details

PLC Control

PLC control is the core of reliable and intelligent operation in an automatic sawmill, ensuring precision, stability, and efficiency in every cutting cycle.

Automatic Return System

The Automatic Return System is designed to streamline material handling and maximize efficiency in automatic sawmill operations by automatically transferring sawn boards back to the operator or designated collection area.

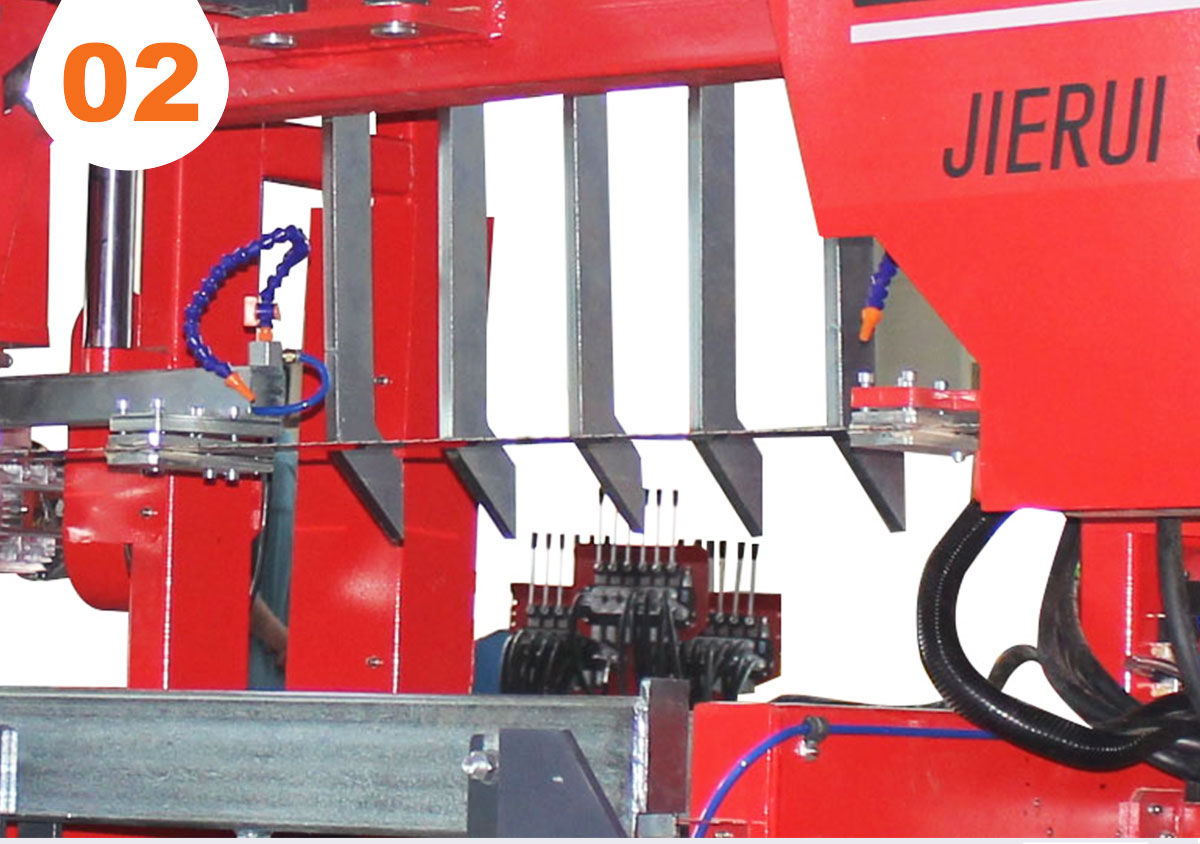

Automatic Saw Blade Guidance System

The Automatic Saw Blade Guidance System is a key technology that ensures high cutting accuracy, stability, and long blade life in automatic sawmills.

Pre-Cutting System

The Pre-Cutting System is an advanced feature in automatic sawmills designed to optimize the cutting process, improve efficiency, and ensure precision before the main sawing operation.

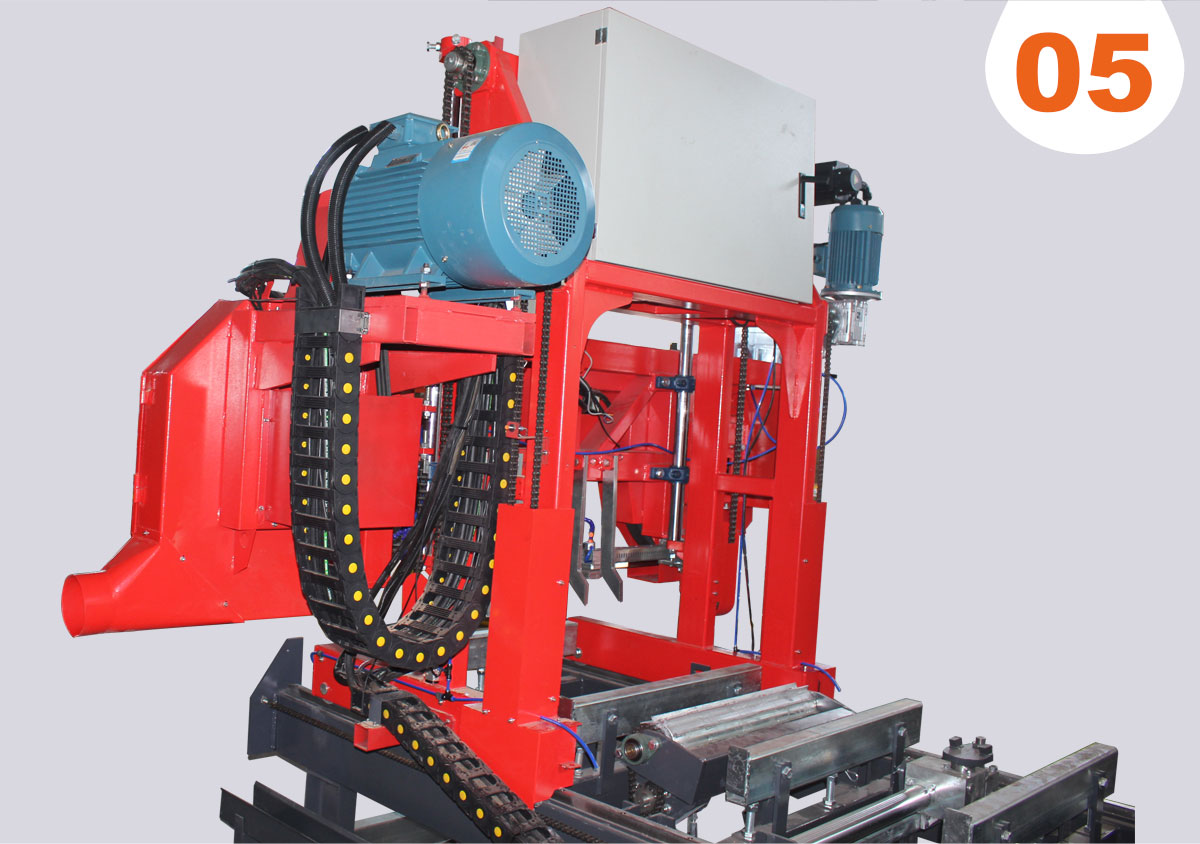

More Power Options

Modern automatic sawmills offer multiple power options to meet different operational needs, production scales, and energy availability. This flexibility ensures that your sawmill can operate efficiently in any setting.

Product Display

Make an inquiry now and receive a FREE product brochure loaded with vital product information and creative inspiration. Join us at JIERUI Machinery Equipment Co., LTD to elevate your operations and experience the future of machinery!

Related Products

Related News

Submitted successfully

We will contact you as soon as possible